Cylinder Wrap System

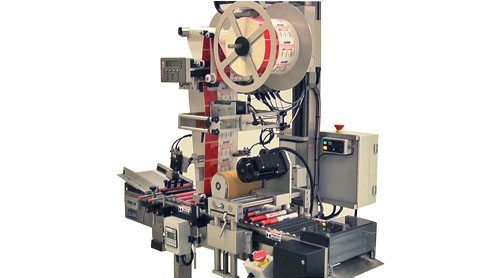

This EconoLine labeling system is a compact and economically-priced system designed specifically to apply a single label on a wide variety of round containers. This system is ideal for applications requiring up to 150 products per minute.

The TechLine Vac-Wrap system is a front/back labeling system designed specifically for the needs of the wine industry. The unique design of the vacuum wrap station allows front/back labels, dispensed from separate rolls, to be applied to round contains at up to 160 products per minute.

This premium quality high speed non-stop zero downtime labeling system is designed for wrap labeling 24/7 operation at speeds in access of 300ppm. This labeling system features all overhead electronics, internationally compliant guarding, Allen-Bradley© PLC control, touchscreen operator interface.

This technically advanced front / back labeling system is designed to accommodate a wide variety of flat sided or oval containers. An optional third or fourth applicator may be added for front/back/neck applications or to provide non-stop zero downtime labeling. In addition, a wrap station may be added for round containers. Production rates of up to 250 ppm are possible with the TechLine.

This custom system is designed specifically for us in hazardous or highly corrosive environments, where only 316 stainless steel can be used. It may be configured in any number of applications including front, back and wraparound applications. Additional features include Allen Bradley PLC control and color touchscreen operator interface.

This custom labeling system may be manually or robotically loaded, and is designed specifically to label tubes in a horizontal configuration, in sizes ranging from 1/2 inch to 3 inch in diameter. The system shown is designed specifically for caulk tubes and features custom escapement infeed, all stainless steel construction and operates at a speed of up to 100 ppm.

This custom system is designed for small diameter tubes, such as lipstick, lip balm, mascara, cosmetic pencils and similar products. Speeds of up to 200 products per minute are possible with this system.